RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

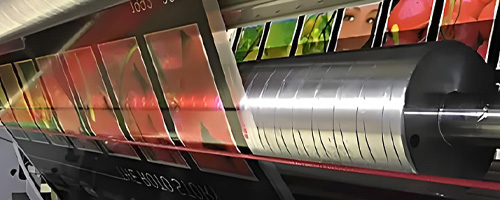

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

2025 UV ink buyer’s guide: how to evaluate manufacturers based on compliance, technology strength, product quality, and supply-chain security. Updated for GB 30981.2-2025.

Nov 26 2025

Learn why environmental gravure ink does not automatically meet food-contact compliance. This guide explains GB 4806.14-2023, FDA 21 CFR 175.300, EU 10/2011 limits, key migration indicators, compliance risks, and best practices for food packaging printers

Nov 19 2025

With carbon-neutral goals and tighter eco-regulations (China GB 38507-2020, EU 10/2011) in place, this buyer’s guide explains what printing firms must consider when choosing eco-friendly gravure inks—covering compliance, technical fit, cost control and se

Nov 12 2025

Discover the key compliance, printing, and performance requirements that water-based flexographic inks must meet for direct food contact packaging under FDA, EU 10/2011, and GB 4806.14-2023 standards.

Nov 05 2025

How Zhongzhixing’s StarColor food-grade water-based inks helped a US quick-serve packaging printer meet FDA & California requirements, improve production efficiency and cut costs.

Oct 29 2025

Discover how low migration UV inks minimize photoinitiator residues through optimized formulation, reactive initiator selection, resin synergy, and additive control to ensure food safety compliance.

Oct 22 2025

Learn about UV printing ink migration testing methods, including EU 10/2011, GB 4806.14-2023 standards, and key technologies such as SPME-GC-MS and HPLC used to ensure the safety of low-migration UV inks for food and pharmaceutical packaging.

Oct 15 2025

Discover how modern flexographic inks—especially water-based and UV-curable systems—help food packaging manufacturers reduce VOC emissions, meet global regulations, and enhance printing performance while ensuring food safety.

Oct 09 2025

Discover key additives that improve the scratch resistance of UV flexographic inks for food packaging. Learn how to enhance durability and protect printed surfaces.

Sep 25 2025

Discover how StarColor water-based flexographic inks transformed napkin printing with food-safe compliance, VOC reduction, higher print quality, and significant cost savings for large-scale paper product manufacturers.

Sep 17 2025