Case study : Starcolor Water-Based Ink Enables North American Printers to Meet Food Safety Standard

Date: Oct 29 2025 From: Star Color Views:

A North American quick-service packaging printer (A-Printer) adopted Zhongzhixing's StarColor export food-grade water-based ink to meet evolving FDA and California requirements, stabilize supply and improve print performance and costs.

Background — dual pressure from compliance and supply

A-Printer (an Ohio-based packaging printer supplying regional quick-service restaurants) faced three intersecting challenges before working with Zhongzhixing:

- Regulatory tightening: California’s chemical and labeling requirements and strengthened scrutiny of food-contact migration by US authorities raised the bar for ink formulation and testing.

- High local cost & unstable supply: North American food-grade water-based inks were expensive (typical local market prices were notably higher than some export alternatives) and supply lead times were long, squeezing margins.

- Technical fit: Existing inks failed to keep adhesion and oil/heat resistance for hot, greasy fast-food use (e.g., fries at 75°C for extended holding times).

Key regulatory and market drivers

Notably, California and US food-contact rules have been evolving — affecting the allowable presence of certain phthalates, heavy metals and the required migration testing protocols. For market players exporting to North America, preemptive compliance testing and traceable documentation are essential.

Zhongzhixing's export solution: compliance, customization, and supply reliability

1. Compliance-first testing

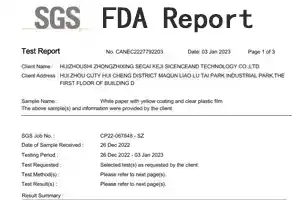

To shorten validation cycles for A-Printer, Zhongzhixing completed pre-export third-party testing and provided certificates showing:

- FDA 21 CFR 175.300 screening by an accredited lab: example results reported by zhongzhixing prior to export showed specific migration at 0.005 mg/kg (50% of the commonly used 0.01 mg/kg benchmark in many migration test scenarios) and low solvent residuals on finished articles.

- California/Prop-65 relevant screening for phthalates and other restricted markers, with phthalate levels reported below the lab’s applicable guidance thresholds used for supply-chain acceptance.

2. Technical customization for quick-serve packaging

Formula adjustments targeted heat and oil resistance required by hot, greasy food service:

- Resin system: an acrylic-epoxy composite resin increased film robustness and heat resistance; 75°C hot-food simulation maintained 5B adhesion with no softening or delamination.

- Oil barrier additives: targeted additives created a dense surface film that passed simulated grease penetration tests (ASTM-style checks) at an industry-acceptable level.

- Fast-drying optimization: ink viscosity was tuned to ~28–32s (Zahn cup #4 @25°C), paired with 45°C hot-air drying to enable full production speeds (300 m/min) with full cure in ~2 seconds on the plant’s flexo equipment.

3. Export and supply support

Zhongzhixing provided export-ready packaging (20 kg food-grade sealed drums with English labels, SDS and compliance IDs), coordinated logistics via L.A. port clearing, and remote technical onboarding in English to reduce the customer’s commissioning time and risk.

Outcomes — measurable business impact

Following the first delivery (May 2024) and a short ramp period, A-Printer reported:

- Compliance & new orders: Third-party lab testing passed FDA and the referenced California checks; A-Printer retained an existing 1.2M-unit/yr fries-box contract and won an additional local quick-serve chain (estimated +$800k annual revenue).

- Quality and throughput: Press speed rose from 250 to 300 m/min; per-shift output increased, complaints dropped from 12% to 0.8%, and the customer moved A-Printer from vendor to core supplier, increasing share from 30% to 45%.

- Cost & margin: Ink procurement cost fell ≈20% vs previous supplier; combined with fewer rework/detection costs, profit margin rose from ~8% to ~13%; inventory turn improved and working capital pressure eased.

Why this case matters

This project illustrates a repeatable export playbook for ink manufacturers targeting developed-market food packaging:

- Pre-validate formulations against target market food-contact rules;

- Provide technical fit (resins/additives + process guidance) to replicate in the local press environment;

- Back exported products with logistics, labeling and local-language technical support so the customer can onboard quickly with low operational risk.

Contact

To discuss StarColor food-grade inks for export markets, request technical data sheets, or arrange a trial shipment and on-site commissioning, please contact Zhongzhixing’s export team.

RU

RU EN

EN CN

CN