What is gravure printing?

Date: Aug 24 2024 From: Star Color Views:

1 Principles of gravure printing technology

(A) Basic Concepts

Definition of Gravure Printing

Gravure printing is a printing technique that involves engraving recessed ink cells (or "cells") onto the surface of a printing plate (typically a cylindrical form called a gravure cylinder). These cells store ink, which is then transferred to the substrate during the printing process. The shape and depth of the cells are designed according to the graphic requirements. Variations in cell depth and size allow different amounts of ink to be held, creating rich color and tonal effects on the substrate.

Differences from Offset and Flexographic Printing

Gravure printing fundamentally differs from offset and flexographic printing in plate structure and ink transfer principles.

- Offset printing uses a lithographic plate where image and non-image areas are nearly planar. It relies on the oil-water repulsion principle to transfer ink via a rubber blanket.

- Flexographic printing employs flexible plates with raised image areas. Ink is transferred through the elastic deformation of the plate, making it suitable for flexible materials.

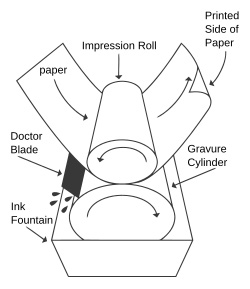

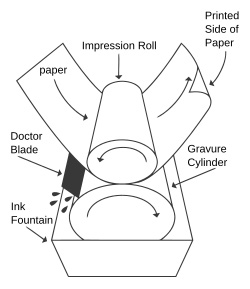

By contrast, gravure printing features recessed image areas that directly hold ink in cells. During printing, the ink is transferred to the substrate under pressure from an impression roller, eliminating the need for intermediate components. This gives gravure printing unique advantages in ink transfer efficiency and print quality.

(B) Working Principles

Ink Cell Storage and Transfer Mechanism

In gravure printing, ink is first supplied to the gravure cylinder surface from an ink pan, filling the cells. A doctor blade then scrapes off excess ink from the cylinder surface, leaving only the ink within the cells. As the gravure cylinder contacts the substrate and rotates under pressure from the impression roller, the ink in the cells is transferred to the substrate, forming the printed image.

The shape and structure of the cells (e.g., diamond, square, or hexagonal) determine ink capacity and release characteristics.

Depth Control Logic (Cell Depth vs. Ink Volume)

Image tonal depth is controlled by adjusting cell depth. Deeper cells hold more ink, producing thicker ink layers on the substrate with darker, more saturated colors. Shallower cells hold less ink, resulting in lighter tones.

During plate-making, precise control of cell depth and opening area ensures accurate tonal and color reproduction. For gradient effects, gradual variations in cell depth enable smooth color transitions.

(C) Core Components and Functions

Gravure Cylinder Structure (Copper Layer / Chromium Layer / Engraving Techniques)

A gravure cylinder typically consists of:

- Steel base: Provides mechanical strength and stability.

- Copper layer: Electroplated onto the base, this layer is engraved to create the cells. Copper’s ductility and machinability allow precise cell formation.

- Chromium layer: A hard, wear-resistant coating electroplated over the copper to protect against abrasion from the doctor blade and substrate during printing.

Engraving techniques include traditional chemical etching and modern laser engraving, which create the cell patterns on the copper layer.

Doctor Blade System: Function and Precision Requirements

The doctor blade removes excess ink from the cylinder surface, ensuring only cells retain ink for printing. Made of high-hardness materials (e.g., stainless steel), the blade’s edge is finely ground for sharpness and straightness.

Precision is critical:

- Blade angle and contact pressure must be uniformly controlled to avoid incomplete ink removal or cylinder damage.

- Pressure is typically measured as force per centimeter of blade length (e.g., 20–40 N/cm).

- Proper alignment ensures consistent ink transfer and print quality. Deviations in pressure or blade condition may cause streaking or uneven prints.

2 Characteristics of gravure printing

2 Characteristics of gravure printing

Thick ink layer: The concave pit design of gravure printing allows ink to be fully filled and retained in the pits, thereby forming a thick ink layer during the printing process. This feature not only enhances the three-dimensional sense of printed materials, but also makes the colors more rich and full.

Vibrant colors and high saturation: Due to the thick ink layer, gravure printing can present more vibrant and saturated colors.

High printing plate durability: gravure printing plates are generally made of metal with strong wear resistance, which can maintain a high plate life during high-speed printing and reduce production costs.

Stable print quality: The gravure printing process is mature, easy to operate, and can ensure the stability and consistency of print quality, meeting the needs of large-scale production.

Fast printing speed: Thanks to its efficient printing mechanism, gravure printing can achieve fast and continuous printing. Currently, the mainstream gravure printing on the market is about 200 meters per minute.

3 History of gravure guided development

Gravure printing is one of the four major printing methods. The pattern on the printing plate is lower than the blank area. During printing, the entire plate is covered with ink, and then the surface is wiped to leave only ink on the pattern area, which is transferred to the substrate and becomes the printed product.

In the mid-15th century, the prototype of gravure printing began to emerge, mainly through manual carving on copper or steel plates to complete the production of printing plates. This method, although primitive, laid the foundation for the development of gravure printing technology.

At the beginning of the 17th century, chemical etching was applied to the production of gravure printing plates, which improved the efficiency and quality of plate making. The specific method is to apply a layer of acid resistant and corrosion-resistant wax on the surface of the copper sheet, and then use a steel needle to draw the pattern, so that the wax layer is damaged, exposing the steel surface, and then forming pits through the corrosion process.

1878: Photogravure technology was born, which uses photography to produce film and uses carbon paper as an intermediate to greatly improve the quality and speed of plate making. The emergence of this technology marks an important step forward for gravure printing from manual engraving to mechanization and automation.

In the mid-20th century, the emergence of electronic engraving intaglio technology further promoted the development of intaglio printing technology. Electronic engraving intaglio relies on the simultaneous changes in surface area and depth of the mesh holes to reflect the depth of the layers, enabling the intaglio printing process to replicate higher quality high-end printed products.

4 Application areas of gravure printing

Packaging industry: gravure printing is the most widely used in the packaging field. Whether it is packaging for food, medicine, or household items, gravure printing can enhance the attractiveness and market competitiveness of products with its exquisite pattern and text printing capabilities.

Publishing industry: In the field of high-definition text and image printing such as magazines and books, gravure printing also plays an important role. It can ensure clear text and delicate images, providing readers with a better reading experience.

Finance and Insurance: Products such as checks, bank cards, certificates, insurance policies, etc. that require high fidelity and anti-counterfeiting security performance are often printed using gravure printing technology.

Cosmetics and personal care: Packaging, labels, stickers, etc. for cosmetics and personal care products are often printed using gravure printing. Its attractive design and illustration printing ability can attract consumers' attention and enhance the brand image.

Other industries: In addition, gravure printing is widely used in industries such as catering, construction, and home furnishings. For example, menus, promotional materials, posters, outdoor billboards, etc. can all achieve exquisite and durable printing effects through gravure printing.

Advantages: gravure printing occupies an important position in the printing industry due to its thick ink layer, bright colors, durable printing plates, stable print quality, and fast printing speed. It can not only meet the printing needs of various complex patterns and texts, but also adapt to the requirements of large-scale production, providing high-quality printing services for various industries.

Disadvantage: With the increasing awareness of environmental protection and intensified market competition, gravure printing also faces some challenges. On the one hand, with the increasingly strict environmental regulations, solvent based inks are mostly used in gravure printing. Not environmentally friendly.

On the other hand, the rapid development of new printing technologies such as digital printing has also had an impact on the market share of gravure printing.

6 Conclusion and ProspectIn summary, gravure printing, as a mature and efficient printing technology, plays an important role in various fields such as packaging, publishing, and finance. Faced with future challenges and opportunities, the gravure printing industry should continue to strengthen technological innovation and process improvement, improve environmental performance and production efficiency.

Many gravure printing manufacturers have started to switch from solvent based ink to water-based ink. Huizhou Zhongzhixing Color has also successfully developed water-based ink for gravure printing, which not only makes gravure printing more environmentally friendly but also reduces the cost of transformation for gravure printing enterprises.

RU

RU

EN

EN

CN

CN