RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

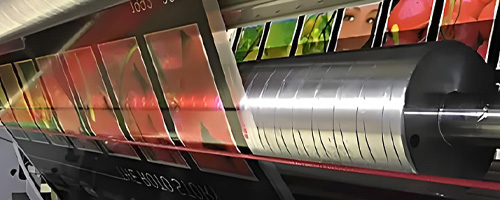

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

Case study on Starcolor water-based flexographic ink for diaper BOPP film printing, demonstrating low odor, strong adhesion, and stable high-speed performance for baby care packaging.

Jan 21 2026

Discover how gravure printing ink performance directly impacts color consistency and printing stability. Learn how Starcolor water-based gravure inks deliver precise color control, stable high-speed printing, and low-VOC compliance for packaging applicati

Jan 14 2026

What is the difference between vegetable-based ink and water-based ink? This article explains their definitions, formulations, performance, applications, and costs to help packaging printers choose the right eco-friendly ink.

Jan 07 2026

Discover how Zhongzhixing water-based flexographic ink helped a leading Thai paper cup printer achieve VOC compliance, improve print quality, and reduce production costs in food packaging.

Dec 31 2025

Explore real global cases where printing inks in food packaging migrated harmful substances into food, highlighting why food contact inks must be strictly controlled and compliant.

Dec 24 2025

A 2025 regulatory interpretation of the five mandatory compliance standards for direct food contact inks, covering EU and FDA requirements, migration limits, GMP production, sensory safety, and third-party certification for food packaging inks.

Dec 17 2025

Learn the five major warning signs when selecting UV ink manufacturers. Avoid low-quality suppliers, prevent compliance risks, and protect your production efficiency and brand reputation.

Dec 10 2025

Compare UV flexographic (UV flexo) and UV offset (UV litho) inks across process suitability, core performance, application scenarios and cost — choose the right UV ink for your packaging needs.

Dec 03 2025

2025 UV ink buyer’s guide: how to evaluate manufacturers based on compliance, technology strength, product quality, and supply-chain security. Updated for GB 30981.2-2025.

Nov 26 2025

Learn why environmental gravure ink does not automatically meet food-contact compliance. This guide explains GB 4806.14-2023, FDA 21 CFR 175.300, EU 10/2011 limits, key migration indicators, compliance risks, and best practices for food packaging printers

Nov 19 2025