RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge > Ink Pedia

Food-grade ink is specially designed for printing on food packaging, food labels, and food-contact materials with safety in mind. Its formulation and production process must comply with strict food safety standards to ensure that no chemical

Mar 13 2025

Ethylene Oxide (EO) sterilization is a widely used method for effectively eliminating microorganisms, ensuring the safety of medical devices. Accurately determining whether the sterilization process has achieved its intended results is critical.

Mar 10 2025

Sterilization indicator labels are common tools for verifying the effectiveness of sterilization. Their core function is to visually reflect whether the sterilization process is completed through color changes.

Mar 05 2025

Zhongzhixing sterilization indicator ink comprehensively covers a variety of sterilization methods. Whether it is steam sterilization, ethylene oxide sterilization, or hydrogen peroxide plasma sterilization, etc., it can be accurately adapted.

Mar 04 2025

Sterilization is the core link in ensuring the safety of medical products. Ethylene Oxide (EO) sterilization, with its high efficiency, is widely used in the disinfection of medical devices, pharmaceutical packaging, and laboratory consumables.

Mar 03 2025

When choosing between water-based ink and alcohol-soluble ink, enterprises need to comprehensively consider multiple factors. If your products have high requirements for environmental protection and safety,

Feb 24 2025

Among the various types of inks, water-based ink and alcohol-based ink have become two common options, each with its unique characteristics and advantages in different application scenarios.

Feb 24 2025

The formulation of water-based flexographic inks requires comprehensive consideration of various components, properties, and printing process requirements. Rational formulation design and process control enable water-based flexographic inks to exhibit exc

Feb 17 2025

Water-based inks are widely used in various industrial production and daily applications. They are essential in industries such as cardboard box printing, medical device labeling, and breathable film processing.

Feb 14 2025

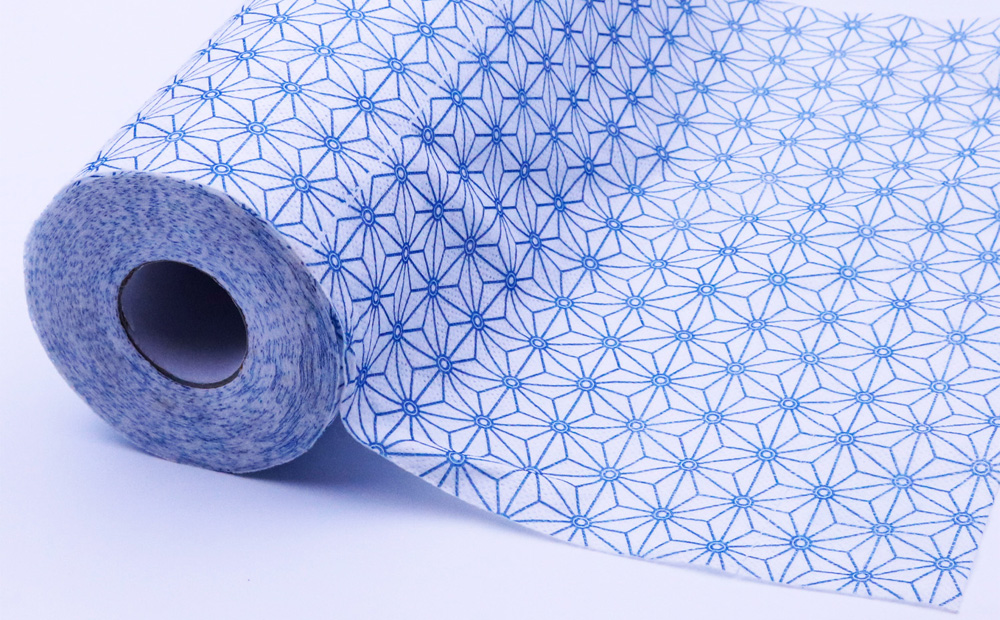

Taking into account various factors such as environmental protection, printing quality, and cost, Zhongzhixing water-based ink is a high-quality choice for non-woven fabric printing

Feb 04 2025