RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge

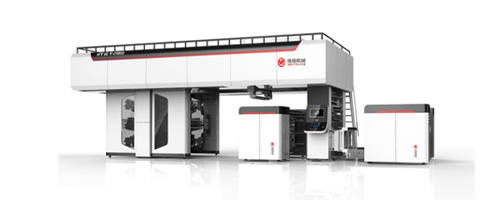

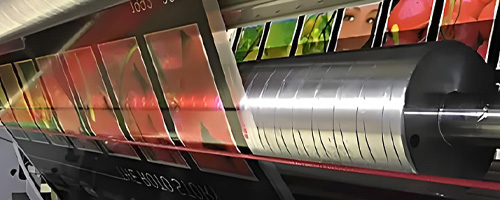

The pattern on the printing plate is prominent, the blank place is concave, through the anilox rollers to transfer ink, generally printed with water-based and UV inks, can reach 400 meters per minute. Flexographic printing is also a kind of letterpress printing.

The printing pattern on the surface of the printing plate is concave, the blank space is protruding, the printing ink layer is very thick, the color is bright, the line is clear, and the saturation is high. Solvent-based ink and water-based ink are available!

The graphic part and the blank part is in the same plane, to the surface of the printing plate inking, only the graphic part of the adsorption of ink, plate work is simple, low cost, suitable for large quantities of printing, mainly using solvent-based inks.

The printing plate consists of a number of small sieve holes, non-graphic part of the mesh is coated with a photopolymer coating sealed, printing adaptability, thick ink layer, three-dimensional sense of strong, bright colors, mainly solvent-based ink.

Flexographic printing is a popular choice for high-speed production of labels, packaging, and other materials. Optimizing efficiency not only reduces costs but also improves overall productivity

Dec 20 2024

Achieving consistent color in flexographic printing is crucial for maintaining quality and customer satisfaction. Color consistency directly impacts brand identity and reduces waste, making it a top priority for printers.

Dec 19 2024

For businesses seeking high-quality, eco-friendly, and FDA-compliant printing inks, Huizhou Zhongzhixing provides a trusted partnership. Their advanced ink formulations ensure vibrant, safe, and sustainable packaging that meets the demands of modern consu

Dec 18 2024

For the food packaging industry, this has led to a significant shift toward eco-friendly FDA-approved food grade inks. These inks ensure both food safety and environmental responsibility while maintaining the high-quality print performance that modern pac

Dec 17 2024

Asia’s food-grade ink manufacturers are at the forefront of delivering safe, sustainable, and high-performing solutions for the global packaging industry. From innovative formulations to strict compliance with safety standards

Dec 16 2024

Food label printing inks play a pivotal role in the food packaging industry by ensuring safety, compliance, and quality. As consumer expectations and regulatory demands continue to rise, innovation in this niche field is more important than ever

Dec 16 2024

As environmental concerns grow, businesses and consumers are increasingly seeking sustainable alternatives in all industries, including packaging. Biodegradable food grade inks have emerged as a revolutionary solution

Dec 13 2024

As a leading player in China's food-grade ink industry, Huizhou Zhongzhixing Color Technology Co., Ltd. stands out with its eco-friendliness, safety, abrasion and high-temperature resistance, vivid colors, rapid drying

Dec 12 2024

Choosing the best food-grade ink for packaging requires careful consideration of safety, performance, and environmental impact. Water-based, UV-curable, and solvent-based inks each have their strengths

Dec 11 2024

Food packaging plays a vital role in ensuring the safety, freshness, and appeal of food products. Beyond aesthetics, one critical aspect of food packaging is the safety of the printing inks used.

Dec 10 2024