RU

RU

EN

EN

CN

CN

Position:HOME > Ink Knowledge > Printing Technology

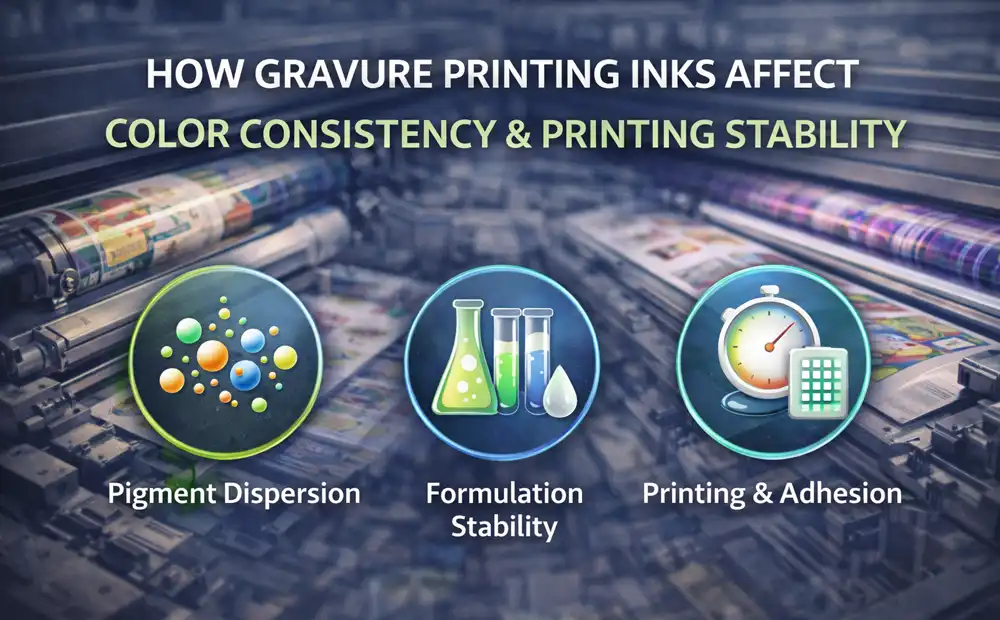

Discover how gravure printing ink performance directly impacts color consistency and printing stability. Learn how Starcolor water-based gravure inks deliver precise color control, stable high-speed printing, and low-VOC compliance for packaging applicati

Jan 14 2026

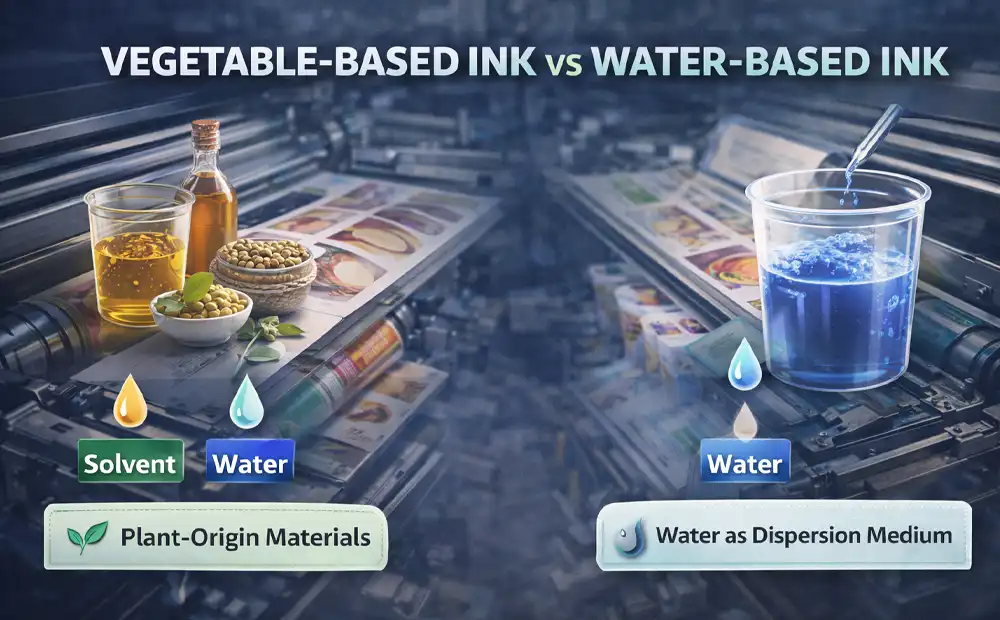

What is the difference between vegetable-based ink and water-based ink? This article explains their definitions, formulations, performance, applications, and costs to help packaging printers choose the right eco-friendly ink.

Jan 07 2026

Explore real global cases where printing inks in food packaging migrated harmful substances into food, highlighting why food contact inks must be strictly controlled and compliant.

Dec 24 2025

Learn about UV printing ink migration testing methods, including EU 10/2011, GB 4806.14-2023 standards, and key technologies such as SPME-GC-MS and HPLC used to ensure the safety of low-migration UV inks for food and pharmaceutical packaging.

Oct 15 2025

Discover key additives that improve the scratch resistance of UV flexographic inks for food packaging. Learn how to enhance durability and protect printed surfaces.

Sep 25 2025

Discover common misconceptions in food-grade ink applications, including compliance, UV curing, water-based ink limitations, post-processing, and substrate compatibility. Learn practical strategies to ensure safety and regulatory compliance in food packag

Sep 10 2025

Discover key tests for assessing food safety of water-based flexographic inks, covering migration, VOC, and raw material compliance for safe food packaging.

Aug 25 2025

Discover effective methods to improve the coverage of water-based flexographic inks on non-absorbent substrates. Learn about ink formulation, surface treatment, and process optimization for consistent print quality.

Aug 21 2025

Discover how to reduce water-based flexographic printing ink consumption by 20%-30% without compromising quality through high-solid-content inks, anilox roller optimization, and thin-layer printing techniques for cost savings.

Aug 13 2025

Learn how a leading packaging enterprise reduced BOPP printing VOC emissions by 87.5% using water-based inks, covering ink selection criteria, process optimization, and environmental/economic benefits for sustainable packaging transformation.

Aug 11 2025

Explore critical environmental durability and safety tests for water-based flexographic inks, including temperature resistance, chemical resistance, VOC content, and heavy metal detection, to ensure print lifespan and regulatory compliance.

Aug 08 2025

Discover key testing methods for water-based flexographic ink performance, covering basic properties (color, fineness, viscosity), application performance (adhesion, drying speed, dot reproduction), and criteria to ensure print quality and production stab

Aug 08 2025

Discover how water-based flexo inks adapt to high-line anilox rollers (600+ LPI) with nano-grinding & low-viscosity formulas. Solve clogging issues, boost precision, and cut costs. Expert guide & case studies included

Aug 04 2025

StarColor Fast Drying Flexographic Ink boosts flexible packaging productivity with 40% faster drying, compatible with BOPP, PET aluminized films. FDA-compliant. Request samples to reduce costs now!

Jul 31 2025

Discover how a Guangdong printing enterprise upgraded high-end paper bag printing through cooperation with Zhongzhixing's flexographic water-based ink, achieving improvements in efficiency, quality and access to international markets.

Jul 29 2025

Learn how to select the right flexographic ink—water-based, solvent-based, or UV—based on ink properties, press types, and printing substrates. A complete guide to flexo printing technology

Jul 28 2025

StarColor flexographic water-based ink has brought considerable economic benefits to enterprises and also solved their environmental compliance issues

Jun 10 2025

Discover the top 5 benefits of using high-speed printing ink in flexographic printing. Learn how faster drying, higher speed compatibility, and better print quality improve efficiency.

Jun 09 2025

Discover how high-speed water-based flexo inks improve efficiency, reduce downtime, and boost print quality. Learn why StarColor® inks are ideal for fast, sustainable printing.

Jun 06 2025

choosing between CMYK and Pantone requires a comprehensive evaluation of multiple factors. By understanding the characteristics and differences of these two color systems

May 30 2025

Water-based inks have 100% degradability in theory, but actual degradation depends on environmental conditions, formulations, and raw materials. Under ideal environments and high-quality formulations

May 28 2025

Deeply analyze the causes of color difference in gravure printing and provide detailed solutions, as well as real-life cases for reference,

May 08 2025

gravure printing is widely used in packaging production for food, pharmaceuticals, tobacco, and other sectors due to its high precision, abrasion resistance, and excellent color performance. However, with the trend toward high-speed and automated producti

May 01 2025

Rotogravure printing is a highly efficient and high-quality printing method widely used in packaging production for industries such as food, pharmaceuticals, and daily chemicals. Despite its mature technology

Apr 30 2025

The cleanliness of gravure rolls directly determines the quality of printed products, color reproducibility, and production efficiency. With the continuous increase in market requirements for printing quality

Apr 28 2025