RU

RU

EN

EN

CN

CN

Position:HOME > SOLUTION > Flexo Printing

As an eco-friendly and efficient printing technology, flexographic printing is becoming increasingly vital in the global printing industry. Its applications are extensive, covering packaging (such as food, pharmaceutical, and consumer goods packaging), label printing, corrugated box printing, flexible packaging, and more. It is widely used in everything from everyday consumer products to industrial packaging.

Flexographic printing offers distinct advantages in terms of its process flow and application scenarios compared to other printing methods. Water-based inks, as a key material in flexo printing, play a crucial role in promoting sustainable and environmentally friendly development. With their low VOCs, low migration, food-grade safety, non-toxicity, fast drying, and excellent adhesion, water-based inks are driving the green evolution of flexographic printing.

In the United States in the early 1920s, people invented the earliest flexographic printing, which was called aniline printing at that time. Due to the toxicity of the aniline dye ink used, it has not been developed.

In 1952, it was renamed as flexographic printing at the 14th Packaging Symposium in the United States.

After the mid-1970s, due to the progress of the materials industry, especially the emergence of polymer resin plates and metal ceramic mesh rollers, there was a qualitative leap in the development of flexographic printing. Becoming the fastest growing printing method worldwide.

The market share of flexographic printing in the United States is 70% in the field of flexible packaging printing;

85% in the field of label printing;

98% in the field of corrugated paper printing;

25% in the field of paper box printing.

In Europe, they also account for 60%, 35%, 85%, and 2% respectively.

Even 20% of newspapers in the United States are printed using flexographic printing

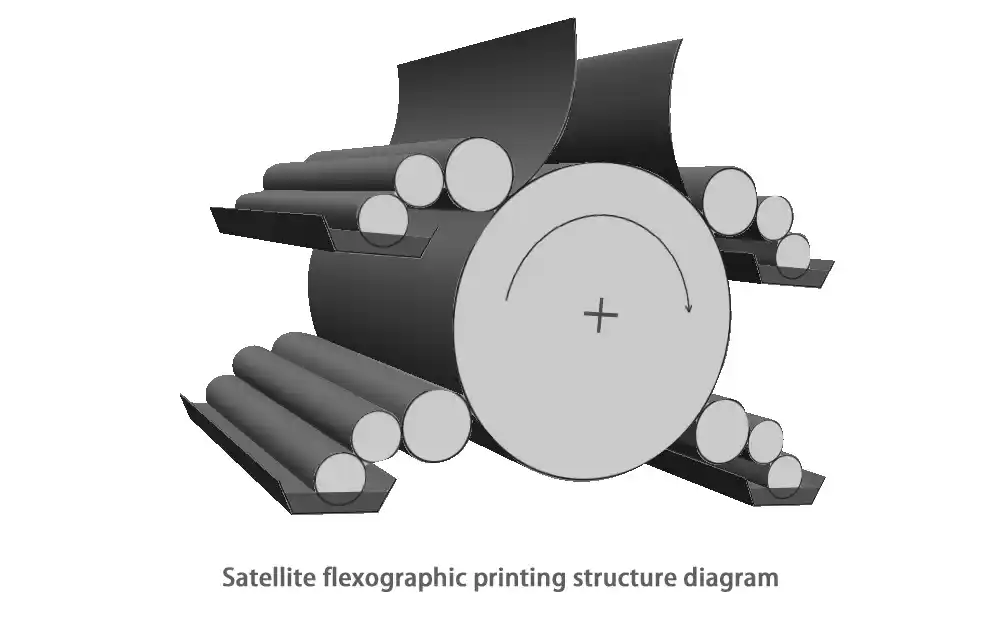

Plate Cylinder: Holds the flexible photopolymer printing plate

Anilox Roll: Precisely meters ink using microscopic cells (typically 200-1000 LPI)

Impression Cylinder: Creates contact pressure for ink transfer

Drying System: UV, IR, or hot air drying depending on ink type

Modern flexo presses achieve speeds up to 750m/min, with makeready times 50% faster than offset for similar jobs.

Flexo printing adapts to paper,corrugated,plastic film substrates via optimized plates & inks selection.

Water-based flexo inks can achieve VOC levels below 1%, meeting strict environmental regulations worldwide.

Plate durability (1+ million impressions) makes flexo ideal for long runs with consistent quality.

UV flexo inks have emerged as a top solution for durable printing, offering excellent adhesion, vibrant colors, and long-lasting results. These inks are cured using ultraviolet light

Jan 13 2025

Flexographic printing is an efficient and environmentally friendly printing technology widely used in the production of food packaging, paper tray, paper cups, and other disposable items.

Nov 16 2024

In the rapidly developing personal hygiene product market, diapers are an indispensable product for newborn and elderly care, and their market demand continues to grow. With the increasing awareness of quality,

Sep 30 2024

Flexographic printing technology, with its unique advantages and wide application fields, plays an increasingly important role in paper bag production.

Sep 11 2024

As an important part of modern printing technology, flexographic printing is particularly outstanding in the field of paper cup printing due to its environmental friendliness, flexibility

Sep 11 2024

PE film, as a widely used plastic packaging material, occupies an important position in various fields such as food, medicine, and industry due to its excellent moisture resistance

Sep 10 2024

aluminum foil is a relatively special packaging material. It has the characteristics of a metal and is also easy to process like plastic film. From preserving food to protecting drugs, from exquisite packaging of cosmetics to protective layers of high-te

Sep 10 2024

Plastic woven bags are a low-cost, durable, and high-capacity packaging material widely used in fields such as cement, fertilizers, feed, and chemical raw materials. With the continuous improvement of packaging appearance requirements

Sep 05 2024

Flexographic printing has become one of the mainstream technologies in the field of packaging printing due to its unique flexibility, low cost, and high efficiency. BOPP (biaxially oriented polypropylene) plastic film is widely used in food packaging

Sep 05 2024

With the increasing awareness of environmental protection and the continuous progress of printing technology, the application of water-based ink for flexographic printing on napkins is receiving increasing attention

Aug 21 2024

As an efficient and environmentally friendly printing method, flexographic printing, combined with the use of water-based ink,achieves rich colors and exquisite patterns on non-woven fabrics

Aug 21 2024

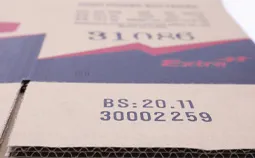

Flexographic Printing, is a printing method for corrugated paper. With its unique advantages and the use of water-based ink, it occupies an important position in corrugated paper printing.

Aug 20 2024