Characteristics of UV ink

Date: Jun 20 2023 From: Star Color Views:

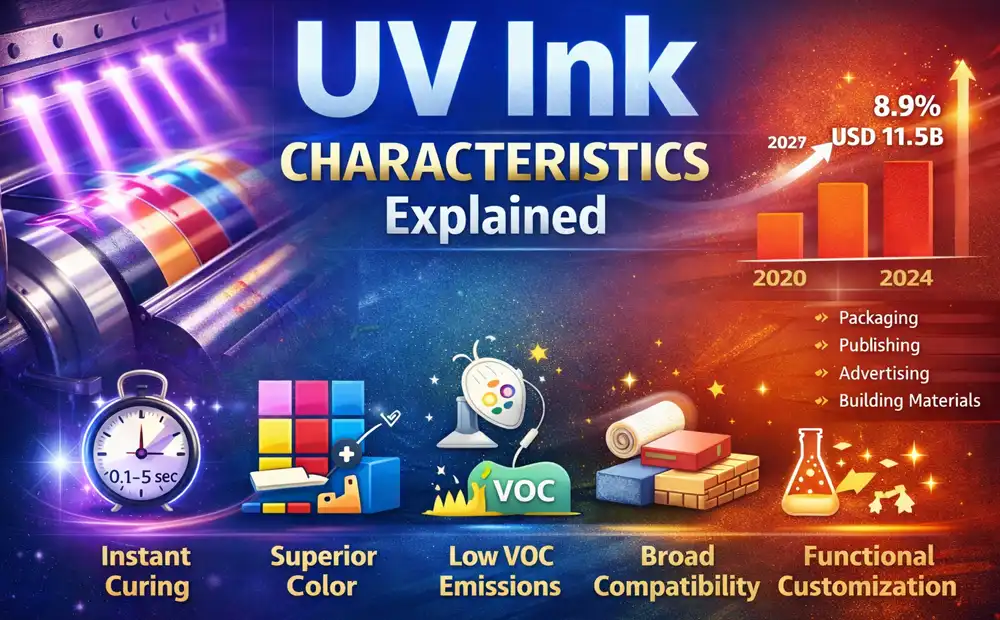

Thanks to its unique photo-curing mechanism, UV ink has become a core consumable across packaging, publishing, advertising, and building materials printing. The global UV ink market expanded from USD 8.2 billion in 2020 to USD 11.5 billion in 2024, achieving a compound annual growth rate (CAGR) of 8.9%.

These competitive advantages—instant curing, high color fidelity, and ultra-low VOC emissions—are all derived from the fundamental characteristics of UV photopolymerization.

This article explains the UV curing mechanism and systematically analyzes five core UV ink characteristics, supported by quantitative industry data and real application scenarios, offering a practical technical reference for printing professionals.

1. Core Principle of UV Ink

UV ink is precisely defined as a solvent-free or low-solvent ink system that uses photopolymer resins as binders and photoinitiators as the curing trigger. When exposed to ultraviolet light within the 200–400 nm wavelength range, monomers and oligomers rapidly polymerize and crosslink, forming a dense three-dimensional ink film.

Unlike conventional solvent-based inks—which rely on solvent evaporation and resin film formation—UV ink curing occurs in three distinct stages without solvent volatilization:

- Light Absorption Stage (0.01–0.05 s): Photoinitiators absorb UV energy and generate active free radicals.

- Chain Propagation Stage (0.05–0.2 s): Free radicals initiate polymerization of acrylate monomers and oligomers.

- Chain Termination Stage (0.2–0.5 s): Polymer chains crosslink, forming a dense, stable ink layer.

This curing mechanism defines the core performance logic of UV inks and explains their fundamental differences from traditional ink technologies.

2. Five Key Characteristics of UV Ink

2.1 Instant Curing

Instant curing is the most decisive competitive advantage of UV ink. With a curing time of only 0.1–0.5 seconds, UV inks cure over 3,600 times faster than solvent-based inks.

- Magazine Printing: Production speeds reach 300 m/min. End-to-end processing time is reduced from 8 hours to 3 hours, improving efficiency by 62.5%.

- Label Printing: At 250 m/min, UV ink eliminates set-off and blocking, keeping defect rates below 0.3% (vs. 2.1% for conventional inks).

- Packaging Printing: Die-cutting and lamination can be performed immediately, reducing order lead time by over 50%.

Key Control Point: Curing energy should exceed 80 mJ/cm². Thick or dark ink layers require 120–150 mJ/cm².

2.2 Superior Color Performance

UV ink formulations contain ≤5% solvent, compared with 30–50% in traditional inks. Pigment loading reaches 35–45%, with particle sizes controlled between 0.5–1.5 μm.

- Dot Reproduction: Stable printing at 175–200 LPI, dot gain ≤8%.

- Color Saturation: CIE Lab testing shows 12–18% higher chroma values.

- Durability: After 1,000 hours of xenon aging, color difference ΔE ≤1.2.

Typical applications include high-end art books, food packaging, and outdoor signage.

2.3 Ultra-Low VOC Emissions

UV ink is a cornerstone material for green printing, with VOC emissions ≤5 g/L, compared with 300–800 g/L for solvent-based inks.

- EU REACH compliance (SVHC-free)

- China GB 30981-2024 (≤10 g/L for food-contact UV inks)

- US EPA standards (no HAPs)

A large printing facility reported VOC emissions dropping from 120 metric tons to 6 metric tons annually, reducing environmental treatment costs by 85%.

2.4 Broad Substrate Compatibility

| Substrate | Resin System | Key Performance | Applications |

|---|---|---|---|

| PE / PP / PVC | Modified polyurethane acrylate | Adhesion ≥4B, abrasion ≥1500 cycles | Food pouches, plastic labels |

| Metal / Glass | Epoxy acrylate | Alcohol resistance ≥50 wipes | Bottle labels, cans |

| Paper / Board | Polyester acrylate | Ink penetration ≤5% | Magazines, cartons |

| Building Materials | High-crosslink acrylate | Weather resistance ≥2000 hours | Outdoor panels, lightboxes |

2.5 Functional Customization

- Spot UV: Gloss adjustable from 30–95 GU.

- Raised UV Ink: Film thickness 10–50 μm, Shore hardness ≥60D.

- Thermochromic / Photochromic UV: Color change ΔE ≥5.0.

- LED-UV Ink: Curing energy reduced to 60–80 mJ/cm², 40% energy savings.

3. Key Control Points and Limitations

3.1 Process Control

- Match ink type with curing system (LED vs mercury lamp).

- Corona treatment for non-absorbent substrates (≥38 mN/m).

- Ink film thickness typically 1–5 μm or 10–50 μm.

3.2 Current Limitations

- Higher initial equipment investment (30–50% higher).

- Deep colors require higher curing energy.

- Low-temperature environments increase viscosity.

4. Future Development of UV Ink Technology

Driven by advances in LED-UV curing and bio-based photopolymer resins, UV inks are evolving toward greater energy efficiency, lower costs, and full-scenario adaptability.

For printers, mastering UV ink characteristics and process control is essential to maintaining competitive advantage. For the industry as a whole, UV ink will remain a key driver of sustainable and high-end printing innovation.

RU

RU EN

EN CN

CN