Application of Food-Grade Ink in Bakery Food Packaging

Date: Mar 29 2024 From: Star Color Views:

When you bite into a fresh croissant or unwrap a gourmet cookie, the last thing on your mind should be the ink on the packaging. But for brand owners, bakers, and packaging manufacturers, the safety of printing inks used on food packaging is a top priority.

With rising consumer awareness and tightening global regulations, food-grade inks—especially water-based food-grade inks—are no longer optional. They are essential for protecting consumers, ensuring compliance, and maintaining brand integrity.

In this guide, we’ll explore:

- What makes an ink “food-grade”?

- Why water-based food-grade inks are ideal for baking packaging

- Key safety standards and certifications

- How StarColor Ink delivers safe, high-performance solutions

1. What Is Food-Grade Ink? Defining Safety in Packaging

“Food-grade” doesn’t mean the ink is edible. It means the ink is formulated and manufactured to prevent harmful substances from migrating into food—even under real-world conditions like heat, pressure, or prolonged contact.

This is especially critical for baking packaging, where:

- Printed boxes or wrappers may come into direct or indirect contact with food.

- Heat from freshly baked goods can accelerate chemical migration.

- Grease and moisture from butter, oils, or condensation can compromise ink stability.

Food-grade inks are designed to minimize migration of substances like:

- Heavy metals (e.g., lead, cadmium)

- Primary aromatic amines (PAAs)

- Volatile organic compounds (VOCs)

- Solvent residues

2. Why Water-Based Food-Grade Inks Are Perfect for Baking Packaging

Among food-grade inks, water-based formulations are increasingly the preferred choice for baking and confectionery packaging. Here’s why:

1. Zero or Ultra-Low VOCs

- Water-based inks use water as the primary solvent, eliminating toxic solvents like benzene, toluene, or xylene.

- Safer for factory workers, reduces air pollution, and meets strict environmental regulations (e.g., EU REACH, U.S. EPA).

2. No Direct Food Contact Risk

- When printed on the outer layer of packaging (e.g., box exteriors, wrapper backs), high-quality water-based inks create a stable film that resists migration.

- Even if the ink is on the inner layer (e.g., printed directly on greaseproof paper), certified food-grade water-based inks are formulated to be inert and non-toxic.

3. Heat and Grease Resistance

- Modern water-based food-grade inks, like those from StarColor, are engineered to withstand:

- High temperatures during baking or storage

- Fatty and oily substances from butter, cream, or chocolate

- Moisture and condensation from cooling pastries

4. Compatibility with Coatings

- Water-based inks work seamlessly with food-safe coatings (e.g., water-based or UV varnishes), adding an extra barrier against migration and improving durability.

3. Global Compliance: Key Certifications to Look For

To ensure your ink is truly food-safe, look for these internationally recognized certifications:

| Certification | Region | Key Focus |

|---|---|---|

| EU 10/2011 (Framework Regulation) | Europe | Sets rules for all food contact materials, including printing inks. Requires migration testing. |

| Swiss Ordinance (SR 817.023.21) | Switzerland & Global Benchmark | One of the strictest lists. Defines permitted substances and limits for ink components. |

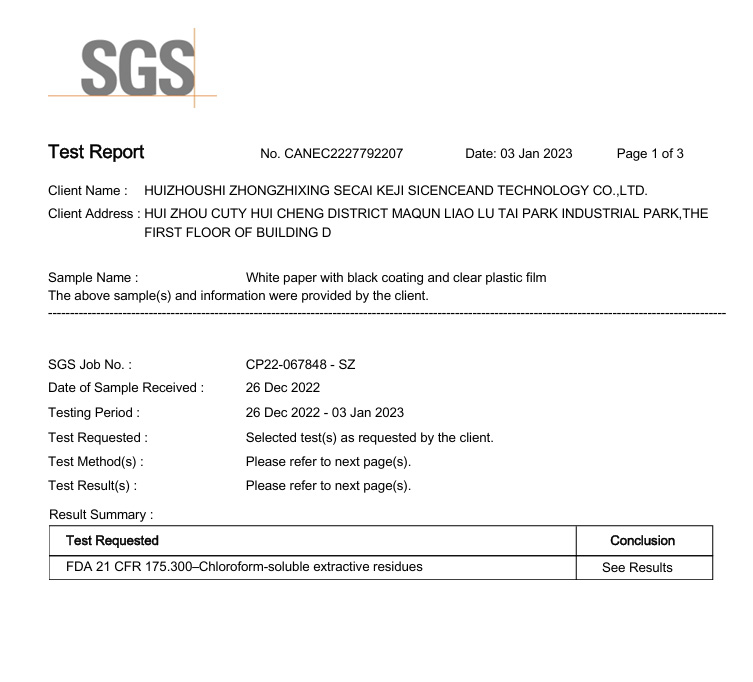

| FDA 21 CFR §175.300 | United States | Governs indirect food additives, including resins and polymers in printing inks. |

| GB 9685-2016 | China | Specifies permitted additives in food contact materials. |

StarColor Commitment: Our food-grade water-based inks are fully compliant with FDA 21 CFR standards. We provide full Declaration of Compliance (DoC) and migration test reports upon request.

4. Real-World Applications in Baking Packaging

StarColor food-grade inks are trusted in a wide range of bakery packaging:

- Bakery Boxes & Cake Wrappers: Printed logos and designs on corrugated or folding cartons.

- Pastry & Cookie Pouches: Flexible packaging with high-barrier films.

- Greaseproof Paper & Baking Cups: Direct food contact applications (requires highest safety level).

- Labeling for Artisan Breads & Gourmet Treats: Premium branding with peace of mind.

Whether you’re packaging artisan sourdough or mass-produced muffins, safe ink is non-negotiable.

5. Choosing the Right Partner: Safety Meets Performance

Food safety shouldn’t come at the cost of print quality. At StarColor Ink, we engineer our food-grade water-based inks to deliver:

- Vibrant, consistent colors for brand impact

- Excellent adhesion on paper, cardboard, and film

- Fast drying for high-speed printing

- Low odor – critical for sensitive baked goods

We work closely with converters and brand owners to ensure every batch meets the highest safety and performance standards.

Conclusion: Safe Ink, Happy Customers

In the world of baking, your packaging is more than just a container—it’s a promise of quality and safety. Using certified food-grade water-based ink is a smart investment in:

- Consumer trust

- Regulatory compliance

- Brand reputation

- Environmental responsibility

At StarColor Ink, we’re not just ink suppliers—we’re your safety partners in the food packaging chain.

RU

RU EN

EN CN

CN