Whether UV ink has special requirements for the substrate

Date: Nov 07 2023 From: Star Color Views:

UV inks are widely used in packaging, signage, construction materials, and decorative printing due to their instant curing, low VOC emissions, and high color density. However, unlike solvent-based or water-based inks, UV inks cure through ultraviolet-initiated photopolymerization.

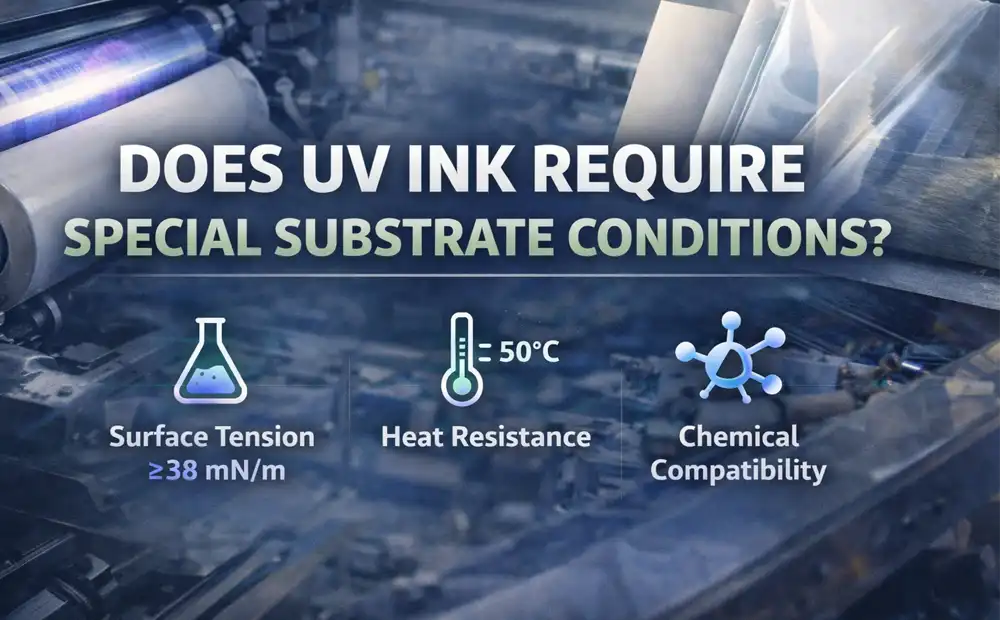

This curing mechanism means that print quality, adhesion, and durability depend not only on the ink and curing system, but also heavily on the properties of the substrate. In real-world production, unsuitable substrates often lead to adhesion failure, incomplete curing, or material deformation. This article explains the key substrate requirements for UV inks and provides practical guidance for printers.

1. Core Substrate Requirements for UV Inks

Surface Properties

UV inks form a dense crosslinked film after curing and rely on surface wetting and molecular attraction for adhesion. Substrates must meet the following conditions:

- Sufficient surface tension: Non-absorbent substrates (plastics, metals, glass) should reach ≥38 mN/m, while absorbent substrates (paper, board) should be ≥35 mN/m to ensure proper ink wetting.

- High surface cleanliness: Dust, oils, slip agents, or oxidation layers can prevent ink bonding and cause peeling.

- Moderate surface uniformity: Excessive roughness may cause uneven ink laydown and color inconsistency.

Physical Performance

- Heat resistance: UV curing lamps generate short-term heat. Thin films such as PP or PE require LED-UV systems with curing temperatures below 50°C.

- Dimensional stability: Paper substrates should maintain a moisture content of 4–6% to prevent warping and registration errors.

- Mechanical strength: Substrates intended for die-cutting or bending must withstand ink film shrinkage without cracking.

Chemical Compatibility

- No adverse reactions between ink components and substrate additives.

- No swelling or softening caused by reactive diluents in UV inks.

2. UV Ink Requirements by Substrate Type

Paper and Paperboard

- Moisture content controlled at 4–6%

- Proper surface sizing or coating to prevent excessive ink absorption

- Specialty papers may require compatibility testing due to metallic or decorative coatings

Plastics (PP, PE, PET, PVC, ABS)

- PP / PE: Require corona or plasma treatment to raise surface tension to ≥38 mN/m

- PET: Light surface treatment recommended; good heat resistance

- PVC: Plasticizer migration must be considered, especially for soft PVC

- ABS: Generally printable without treatment, but temperature control is essential

Metal and Glass

- Thorough cleaning to remove oil and oxidation layers

- Use of dedicated primers (epoxy or silane-based) to enhance adhesion

- Higher curing energy may be required due to UV reflection

Building Materials

- Surface pretreatment such as sanding, priming, or corona treatment

- Substrate and ink must both meet outdoor weather resistance requirements

3. Common Pretreatment Methods

- Corona, flame, or plasma treatment to increase surface energy

- Cleaning using alcohols or alkaline solutions to remove contaminants

- Primers to improve adhesion, seal absorbent surfaces, or enhance smoothness

Conclusion

UV inks place clear and specific requirements on substrates, including surface tension, cleanliness, thermal resistance, and chemical compatibility. Proper substrate selection and pretreatment are essential to achieving reliable adhesion, complete curing, and long-term durability.

By understanding and addressing these substrate requirements, printers can fully leverage the advantages of UV inks, reduce production risks, and achieve consistent high-quality results. As both UV ink formulations and substrate technologies continue to evolve, the range of compatible applications will continue to expand.

RU

RU EN

EN CN

CN