Differences Between Water-based Varnish and Oil-based Varnish

Date: Jun 17 2025 From: Star Color Views:

This article aims to provide a comprehensive overview of the differences between water-based and oil-based varnishes, helping manufacturers, designers, and printers make informed decisions based on their specific needs. By understanding the unique characteristics and application scenarios of each varnish, professionals can choose the most suitable product for their projects, ensuring optimal performance, appearance, and sustainability.

I. Overview of Water-based Varnish

Water-based varnish uses water as the primary solvent, making it a more environmentally friendly alternative to traditional oil-based varnishes. It typically consists of water-soluble resins, pigments, and additives dispersed in water. After application, the water evaporates, leaving a durable protective film on the surface.Applications:

Water-based varnish is widely used in packaging, labeling, paper products, and woodworking. In the packaging industry, it is commonly applied to cartons, boxes, and labels to form a barrier against moisture, abrasion, and UV radiation. In printing, it is favored for adding gloss, matte finishes, or silky textures to printed materials, enhancing their visual quality.

Key Advantages:

- Fast Drying & Low Odor: Unlike oil-based varnishes, which emit strong odors and may take hours to days to dry, water-based varnishes dry rapidly, usually within 30 minutes to 1 hour (depending on coating thickness and environmental conditions).

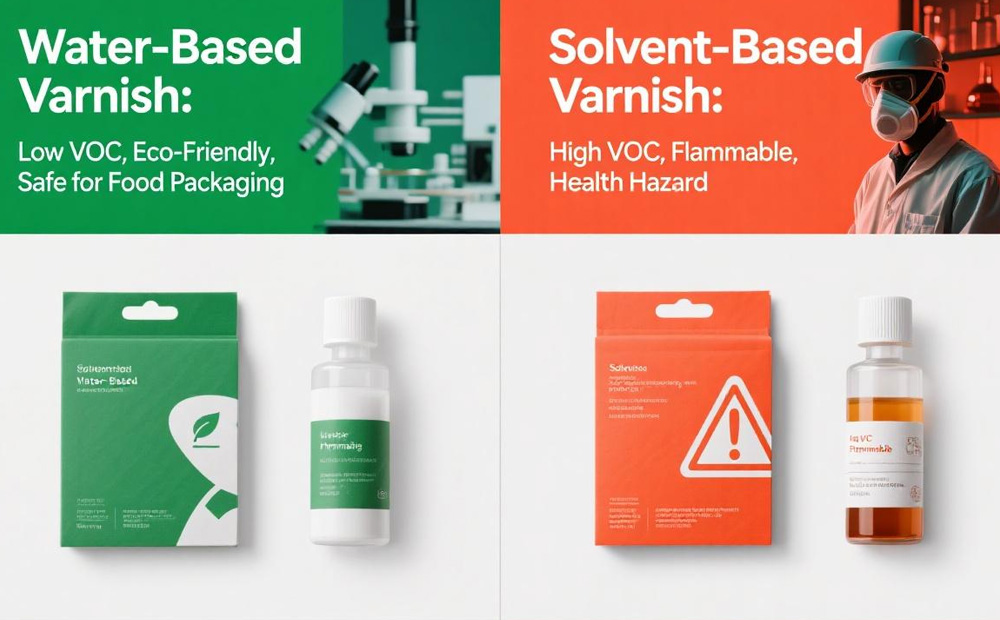

- Environmental Friendliness: With water as the main solvent, water-based varnishes contain fewer Volatile Organic Compounds (VOCs) compared to oil-based varnishes (which are typically formulated with petroleum-based solvents). This reduces environmental impact and complies with strict environmental regulations.

II. Overview of Oil-based Varnish

Oil-based varnish is formulated with petroleum-based solvents and resins, providing a durable and long-lasting coating. It typically contains alkyd resins and solvents like mineral spirits or turpentine. After application, the solvent evaporates, leaving a hard protective film on the surface.Applications:

Oil-based varnish is commonly used in woodworking, industrial coatings, and other scenarios requiring high durability and protection. In woodworking, it is applied to furniture, floors, and outdoor wood to create a rich, glossy finish that enhances the natural beauty of the wood. In industrial settings, it is popular for coating metals, concrete, and other surfaces to prevent corrosion, wear, and chemical damage.

Key Advantages:

- Deep Gloss & Luxurious Texture: Unlike water-based varnishes (which often have matte or satin finishes), oil-based varnishes offer high gloss, giving surfaces a shiny and sophisticated appearance.

- Superior Durability: The hard protective film formed by oil-based varnishes resists scratches, stains, and abrasion. Additionally, it has better moisture and UV resistance than water-based varnishes, making it ideal for outdoor use or high-humidity environments.

Disadvantages:

- Slow Drying Time: Due to petroleum-based solvents, oil-based varnishes dry much slower than water-based ones, often taking hours to days (depending on coating thickness and conditions).

- High VOC Content: Formulated with petroleum-based solvents, oil-based varnishes emit strong odors and contain high VOCs, which may contribute to air pollution and health risks.

III. Comparative Analysis

| Characteristic | Water-based Varnish | Oil-based Varnish |

|---|---|---|

| Drying Time | Fast (30 minutes to 1 hour) | Slow (hours to days) |

| Odor & VOCs | Low VOCs, mild odor | High VOCs, strong odor |

| Environmental Impact | Eco-friendly, cleanable with water | Less sustainable, requires solvent for cleaning |

| Durability | Suitable for packaging, moderate abrasion resistance | Extremely durable, especially for wood |

| Application Ease | Easy to apply and clean | Requires more careful application |

| Gloss Level | Offers satin/matte/silky touch finishes | Provides high gloss with depth |

| Application Scenarios | Labels, cartons, printing coatings | Furniture, floors, outdoor wood |

IV. How to Choose?

The choice between water-based and oil-based varnishes depends on factors such as application type, environmental regulations, and desired finish and texture.- Based on Application Type:

- For printing and packaging, water-based varnish is often preferred due to its fast drying, low odor, and eco-friendliness. It is also ideal for achieving silky or matte effects, creating a softer, natural appearance.

- For woodworking—especially projects requiring high durability and protection—oil-based varnish is the better choice. It is perfect for furniture, floors, and outdoor wood, delivering a deep, glossy finish that enhances wood grain while protecting against wear and environmental factors.

- Based on Environmental Regulations or Sustainability Goals:

If environmental regulations or brand sustainability goals are a priority, water-based varnish is the superior choice. It has lower VOCs and is easier to clean, making it a more eco-friendly option. - Based on Desired Finish and Texture:

The expected coating effect matters: water-based varnishes offer various finishes (satin, matte, silky touch) for a subtle look, while oil-based varnishes provide high gloss for a shiny, sophisticated appearance.

Conclusion

In summary, water-based and oil-based varnishes have distinct characteristics and applications. Water-based varnish stands out for its environmental benefits, fast drying, and low odor, suitable for printing, packaging, and diverse industries. Oil-based varnish excels in durability, making it ideal for woodworking and projects requiring robust protection.When choosing between them, consider the application type, environmental regulations, and desired finish. For professional guidance on water-based varnish solutions, contact Starcolor Corporation today. Our experienced team can assist you in selecting the right varnish for your needs and provide the support to achieve optimal results.

RU

RU EN

EN CN

CN